Omega Twist Spinning Technology

OTW® spinning technology for fashion

What is good for circular knitting and outdoor garments is also good for fashion garments?

OTW® yarn spinning technology creates superior garment constructions not only for activewear but also for the elegant and timeless garments for the urban life. Apart from the comfort and softness the garments made of OTW® yarns have:

- Reduced pilling

- Less hairiness

- Smooth surface

OTW® vs. Ring Spun

What, why, how.

Omega Twist® is the most innovative and unique wool yarn spinning technology of recent years. After four years of research and development, OTW® was designed and developed from the vast experience and knowledge at Südwolle Groups very own Innovation Hub in Südwebs. The Merino wool yarns spun by this spinning technology have a more uniform and smooth appearance and we are constantly working on updating and optimizing the technology.

OTW® technology was originally developed for the woven fabrics industry to improve the efficiency of the yarn during the weaving process, thus obtaining higher quality fabric in both appearance and performance.

Namely: less pilling, more abrasion resistance, more production yield during the manufacturing process and reduced mending and finishing costs generally needed to construct the best worsted Merino wool fabrics.

The OTW® technology provides fabrics and apparel with better anti-pilling performance, clearer appearance and a superior wearing experience. In addition, it doesn’t require any chemical anti-pilling treatment which significantly improves the environmental impact.

- Reduced hairiness and pilling

- Maximized durability and abrasion resistance

- Cleaner surface

- Better elongation and strength

- Higher knittability values (higher speed especially by seamless knitting)

- Soft touch

The overall functional enhancement of Merino wool garments made from OTW® yarns elongates their life cycle and thereby improves the environmental impact of every product containing them.

You don’t know how to start a supply chain?

By joining our network you gain access to a wealth of experience in the industry so we can guide your first steps into starting your own enterprise. Our textile engineers will help bring your ideas to life by supporting your supply chain creation and collaborating with your project when you need a helping hand. From sourcing raw materials to entering the industry’s network, we’re here to shed light on all you need to know and provide a dash of inspiration.

Collaboration

OTW® meets fashion

This time, we cooperated with the Amsterdam based design and development studio KNITWEAR LAB, who used their design & knitting expertise to showcase Biella Yarn’s finest quality materials. A selection of yarns from the new collection book was implemented in a knitted trouser design with a relaxed fit.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationMood

“Easy to wear and easy to match”

In the world of work-life balance struggle – it’s time to appreciate the little moments of joy and fun in our daily lives.

Working with KNITWEAR LAB, Design and Development studio, we decided to focus on a pragmatic solution which will make you feel comfortable and relaxed in every occasion.

Inspiration

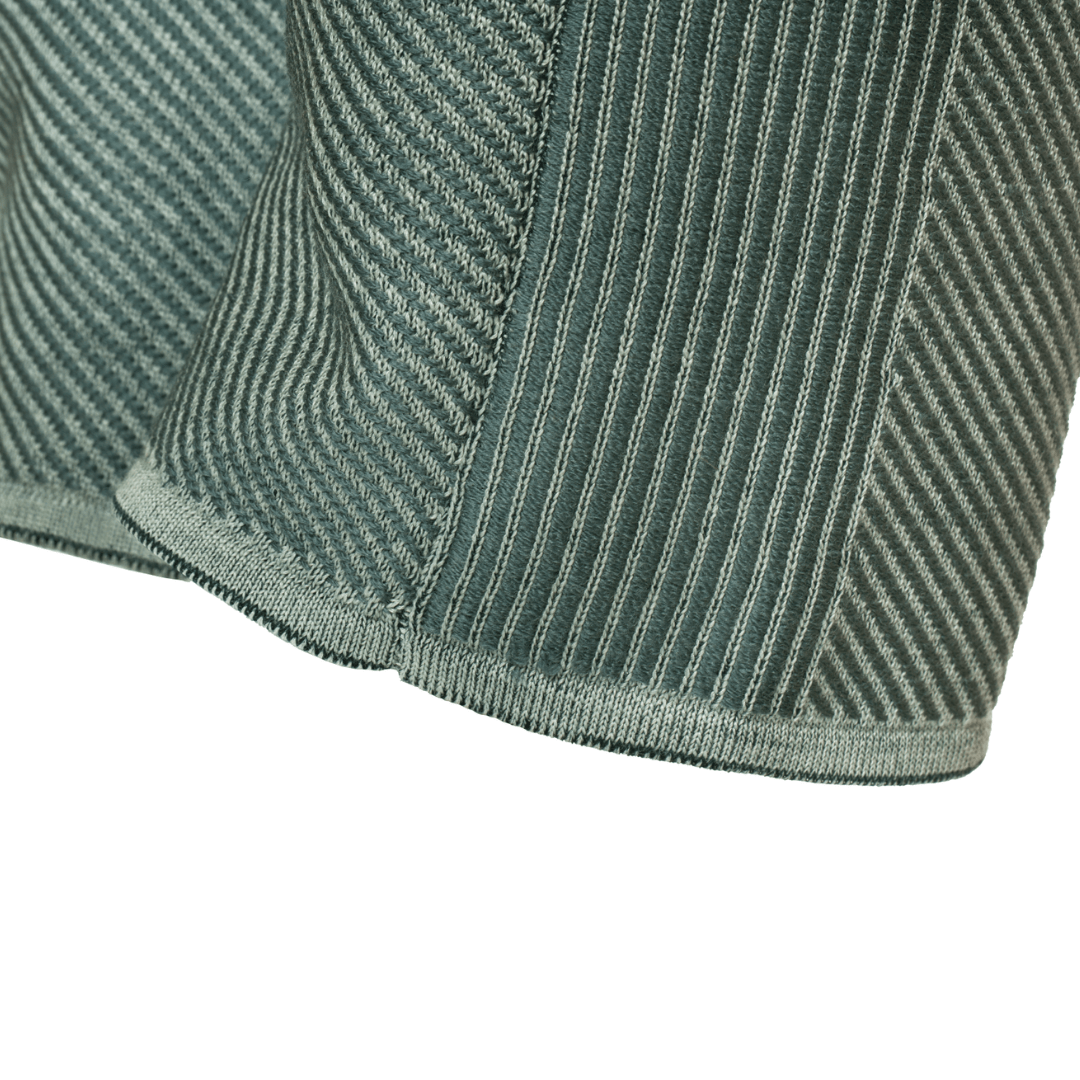

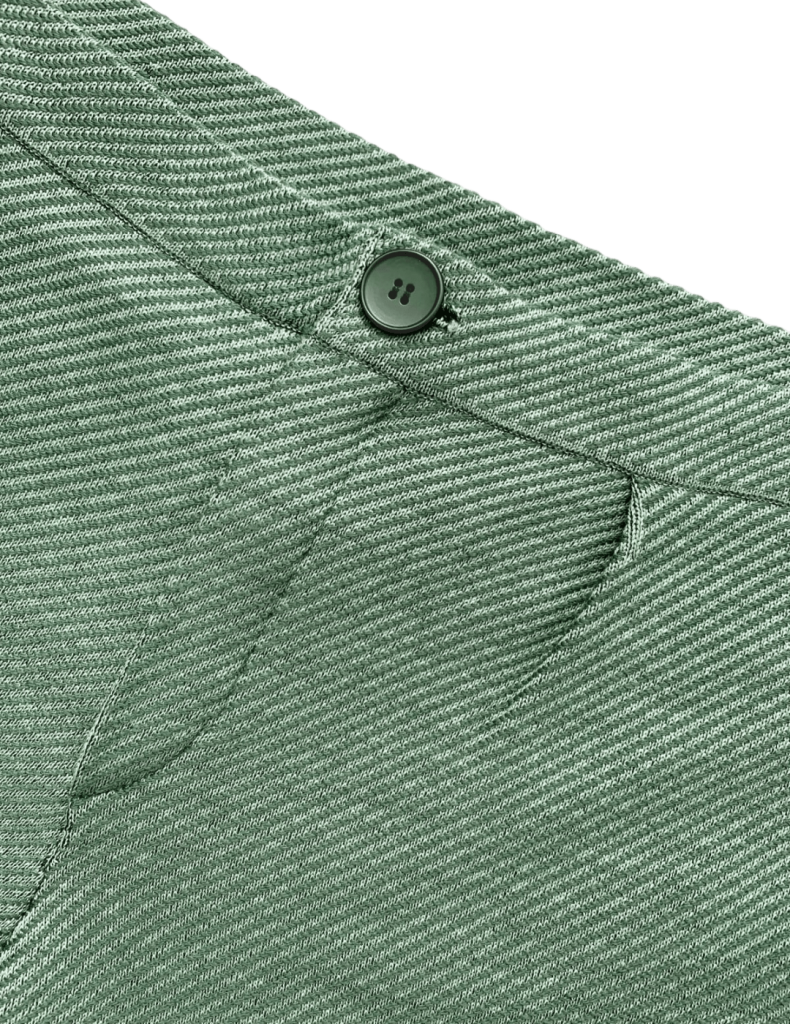

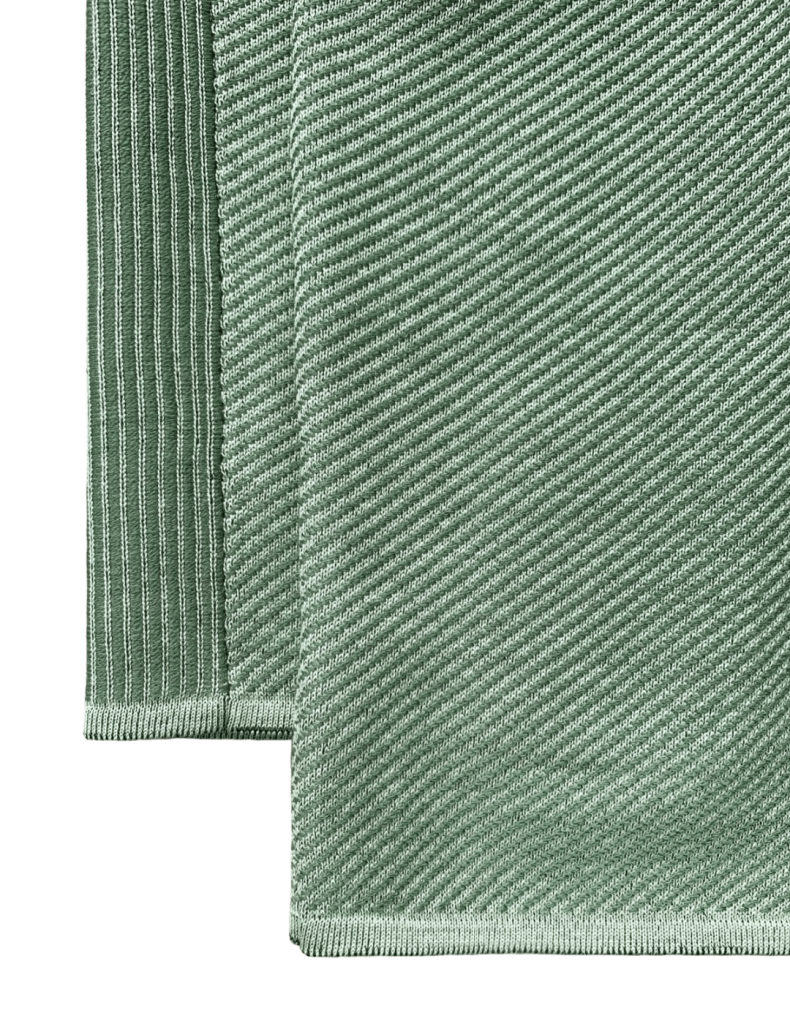

Inspired by the twill-weave of classic blue-jeans, the plating in the knitted base of the fabric combines a lighter green on the inside with a darker tone on the outside. Thus inheriting both a classic appearance and a timeless look, while providing a comfortable fit.

Technology and Function

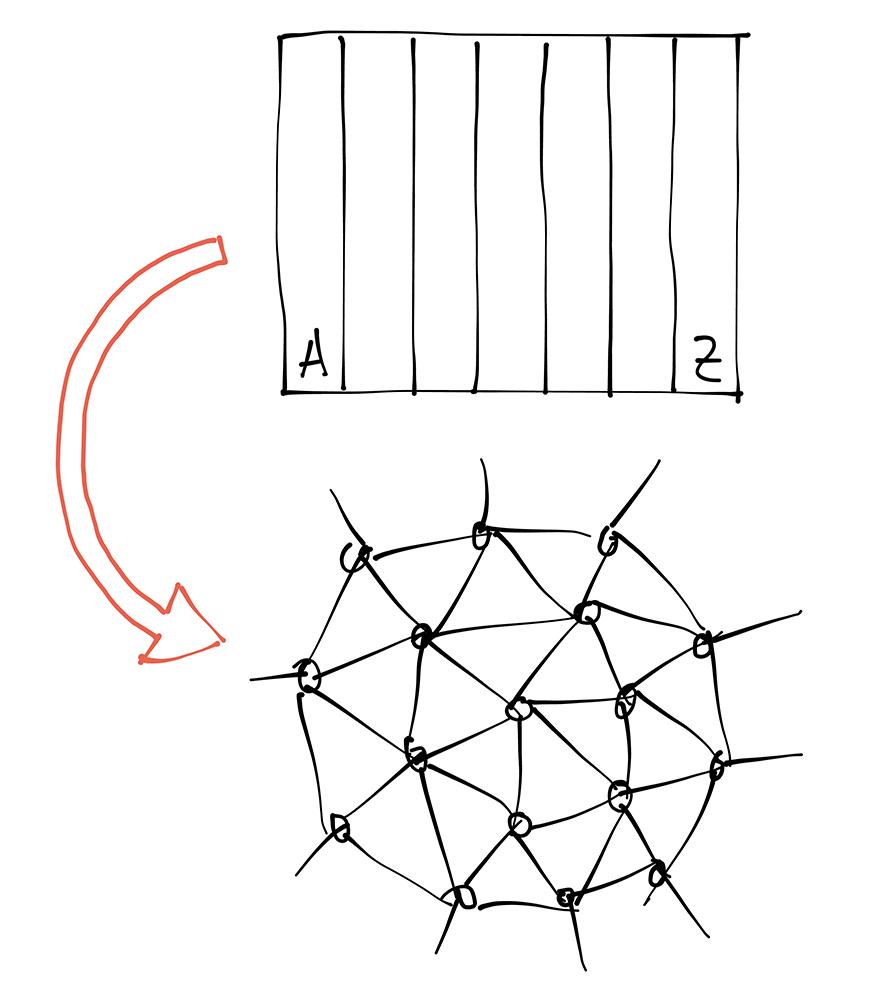

The knitted trousers were developed on a 14gg knitting machine using the The STOLL-weave-in® technology. During this a plated single knit is formed, which leads to a refined structure, with a strong fabric to avoid “knee-pouches”.

The benefits of this technology are being amplified by the smooth surface and high abrasion resistance provided by the OTW® yarn when being weaved in a diagonal design.

This combination of different technologies creates an interesting double-sided fabric feature in the pants, as seen when rolling up the lower part of the leg.

Interested in a collaboration?

If you’re not sure where to start, we can connect you with one of our supply chain managers to find the right innovation for your business.

Garment information

Knitted Trousers

The knitted trousers were developed with use of the STOLL-weave-in® knitting technique, which is laid into a plated single knit base. Knitted entirely with OTW® Onyx Nm 48/2 the garment combines the comfort and softness of wool with refined structure and strong fabric quality.

The plating in the knitted base of the fabric is inspired by the twill-weave of classic blue-jeans, which similarly shows a lighter blue on the inside and a darker tone on the outside of the fabric. In addition, the diagonal weave-in design also emphasises this twill-weave look of jeans.

Garment information

OTW® Onyx Nm 48/2

- 100% Extrafine Merino Wool 19.5 µ anti-shrinkage

- High abrasion resistance

- High pilling performance

- Less hairiness

- Higher strength and elongation

- Odour free

- Biodegradable

- Thermoregulating

- Moisture management

Get your own OTW® garment

1. Choose quantity 2. Enter you company details 3. Order a garment

OTW® Knitted trousers*

120 € | 840 RMB

*Purchase of the garments only possible for B2B partners of Südwolle Group

OTW® Knitted trousers using OTW® Onyx Nm 48/2, 100% Extrafine Merino Wool 19.5 µ, anti-shrinkage

The knitted trousers were developed with use of the STOLL-weave-in® knitting technique, which is laid into a plated single knit base. Knitted entirely with OTW Onyx Nm 48/2 the garment combines the comfort and softness of wool with refined structure and strong fabric quality.

- OTW® Onyx Nm 48/2, 100% Extrafine Merino Wool 19.5 µ, anti-shrinkage

- Odour free

- Biodegradable

- Thermoregulating

- Moisture management