Introducing: Wool denim

A fresh take on lifestyle

Denim carries stories – of work, rebellion, everyday life. It is one of the most recognisable fabrics in the world, shaped by history and worn by millions. For this project, we have taken everything people love about denim and enhanced its familiar cotton face with our beloved Merino wool.

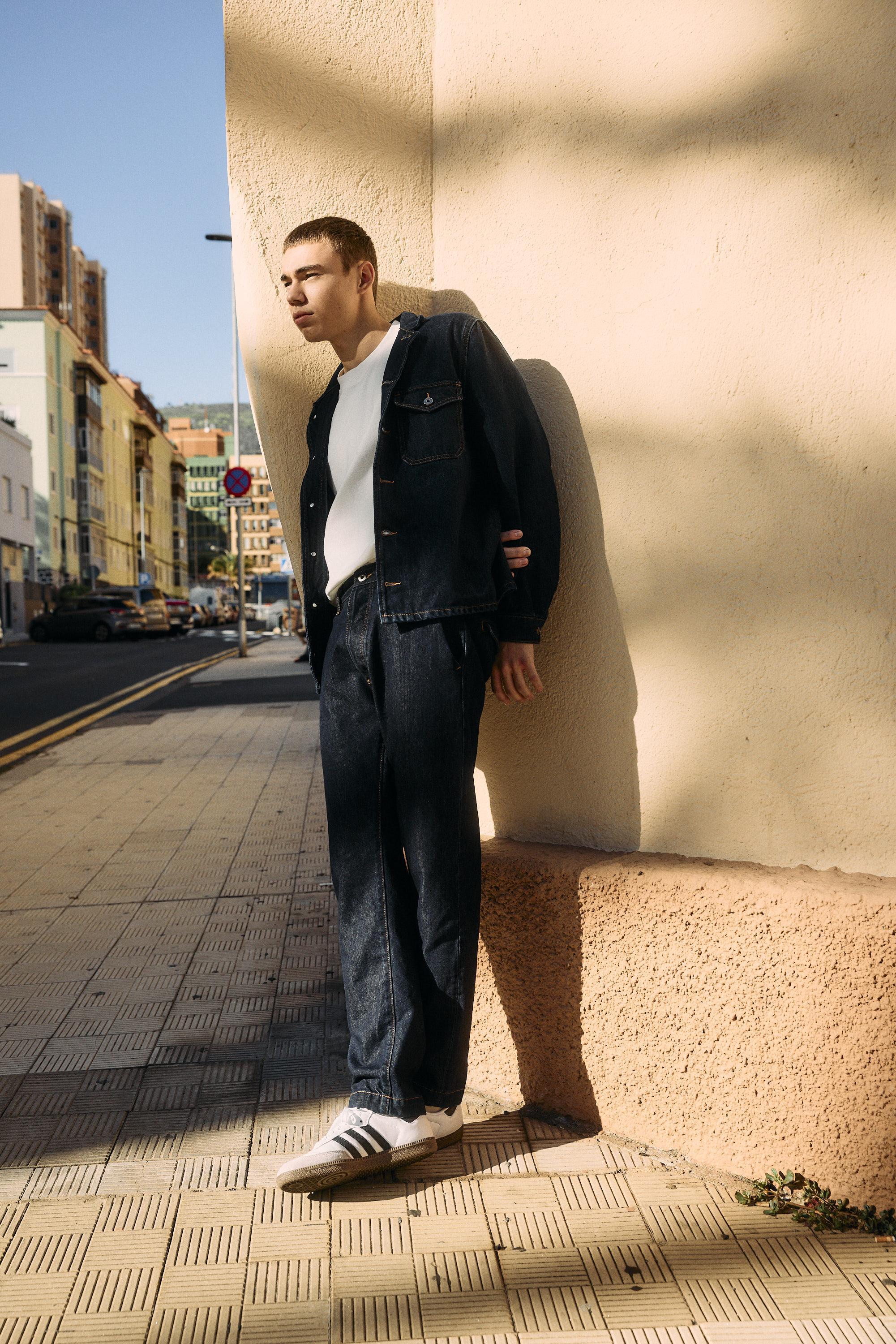

The result is a fabric that stays true to the authentic denim look while feeling softer, more breathable, and thus fitting perfectly into all the moments of your day.

Design concept and inspiration

The vision of this project was to preserve the unmistakable character of denim while elevating it with the softness, drape and natural thermoregulation of Merino wool. The ambition was clear:

- Keep the authentic indigo look that defines denim.

- Add the softness and breathability of Merino, making it comfortable to wear in diverse climates.

- Ensure practicality through easy-care properties, so garments can be machine washed and tumble dried without compromising in quality.

Compared to conventional denim, this fabric feels softer and smoother on the skin while keeping the casual look that makes denim so versatile. It’s relaxed, refined, and made for everyday wear.

Three weights, endless versatility

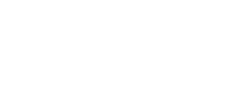

Maintaining the authentic denim look was essential. To achieve this, our partner Berto Industria Tessile selected special cotton warp yarns with the characteristic irregular texture of denim and dyed them with indigo. All three fabric variations were constructed using a 3/1 twill weave, the classic denim structure. By adjusting yarn density, the team created three distinct weights:

- Lightweight: more fluid, ideal for shirts and dresses.

- Mid-weight: versatile, suitable for a wide range of garments.

- Heavyweight: robust, perfect for trousers and structured jackets.

This range gives designers freedom to move between categories while keeping a unified look and feel. The fabric’s non-stretch nature makes relaxed fits the ideal choice.

How the project came together

Designed for impact, built for wearability

Development process and technical challenges

The key technical challenge was to align an indigo-dyed cotton warp with a 100% Merino wool TEC weft: two very different fibres with distinct behaviours in weaving and finishing. Getting the right balance of stability, durability, and a consistent look required several rounds of refinement.

The team experimented with yarn counts, loom settings and finishing techniques to find the perfect balance between structure and softness. The easy-care treatment on the wool was pivotal, ensuring the fabric retained its shape and touch after domestic wash and drying cycles. Finishing was carefully engineered to preserve the indigo vibrancy while allowing the Merino weft to express its natural softness.

Yarn selection and quality testing

The Merino weft was carefully chosen for its smooth hand, fluid drape and compatibility with easy-care maintenance. Alternative wool options were considered less suitable due to potential compromises in comfort or weaving stability, and blended routes risked reducing the signature softness and breathability associated with Merino.

Banda TEC X-Compact

Nm 37/3

100% Merino wool 17.2µ TEC

Regular standard quality checks were performed to ensure durability and performance:

- Dimensional stability

- Washing tests

- Rubbing

- Lightfastness

- Acid and basic sweat resistance

Results and future outlook

The outcome is a versatile denim fabric that feels familiar yet new: authentic in look, but softer and more luxurious to the touch. It brings Merino’s natural thermoregulation for comfort in every season, along with easy-care functionality that supports both machine washing and tumble drying.

Looking ahead, the team sees potential in introducing stretch versions and new finishes, expanding how denim can look, feel, and move in the future.

Interested in your own wool denim garment?

Through our E-Commerce you have the option to order your very own wool denim garment. Just click on the link below and order your preferred piece.

Collaboration that matters

Berto Industria Tessile

Founded in 1887 in Bovolenta (Padova), Berto Industria Tessile is an Italian denim specialist with a heritage rooted in craftsmanship and innovation. At the Bovolenta site, the following steps were carried out:

- Warping

- Indigo dyeing of the warp yarn

- Weaving

- Finishing (washing and stabilising the fabric)

- Quality control

Berto’s approach in this project reflects its philosophy: combining Italian heritage with fabric innovation and bespoke creativity. The result is a fabric that merges soft hand-feel with denim character – selected by brands that value excellence, transparency and personalisation.

The Woolmark Company

The Woolmark Company is a global authority on wool, highlighting Australian wool’s position as the ultimate natural fibre and premier ingredient in luxury apparel. The Woolmark logo is one of the world’s most recognized and respected brands, providing assurance of the highest quality and representing pioneering excellence and innovation from farm through to finished product.