Innovation

Ethics meets performance

The SuperNatural Runner, pioneered by Circle Sportswear, represents a revolution in the running industry—an industry which has been predominantly dependent on oil-based products. In an era where environmental impact is an integral metric, the company’s commitment to ethical, responsible manufacturing is ushering in a new era of accountability. The key to this? Adherence to globally recognised standards, such as the Responsible Wool Standard (RWS), ensuring every step in the production process is traced and audited for animal welfare and land management practices. This meticulous commitment to sustainability – all the more significant given the grim statistic that 95% of running shoes are currently made from oil – is at the core of Circle Sportswear’s ambitious mission.

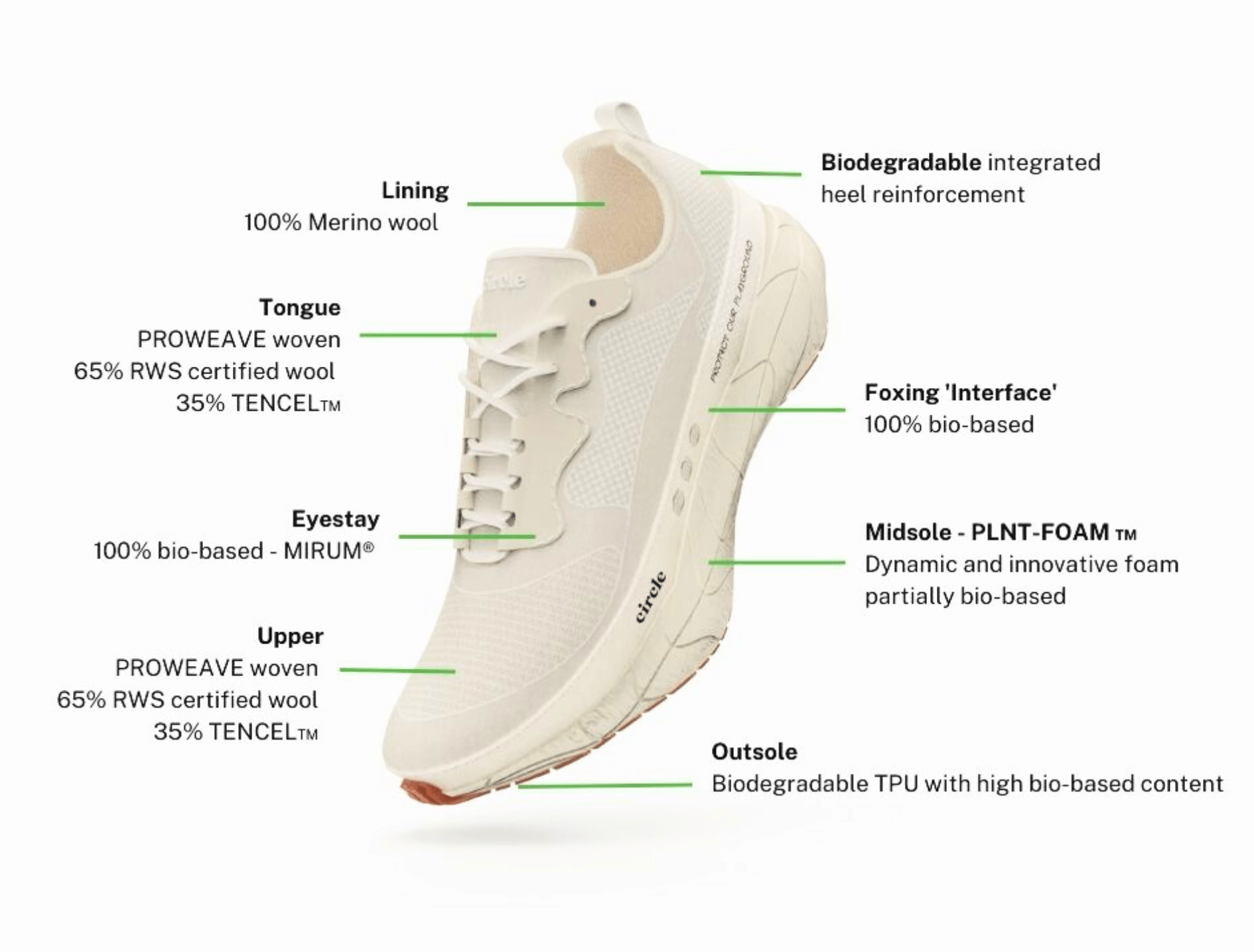

This shoe is the first circular, bio-sourced running shoe made in Europe, harmoniously merging science, technology, and environmental responsibility. Uniquely designed to be disassembled into two parts, the upper portion is entirely biodegradable, constructed from a blend of wool and TENCELTM Lyocell by Lenzing. This part uses the Roller RWS yarn, made of 100% RWS certified wool, demonstrating a commitment to product traceability and animal welfare. Meanwhile, the recyclable midsole can be repeatedly repurposed without any loss in its technical properties, embodying an end-of-life solution.

Additionally, the inclusion of TENCELTM Lyocell by Lenzing and the pioneering PLNT-FOAM™, co-developed with Arkema and partially derived from castor beans, extends this ethos of sustainability and transparency. The culmination of these elements results in a product that minimises environmental impact while guaranteeing optimal comfort for runners, stride after stride. With the SuperNatural Runner, Circle Sportswear redefines what it means to create high-performance, eco-conscious sportswear.

- Sustainable manufacturing

- High-performance capability

- Innovation through natural materials

- Reduced environmental impact

- Optimised running comfort

- Traceable raw material through RWS certification

What, why, how.

The development of the SuperNatural Runner by Circle Sportswear marks a significant shift in the running shoe industry, which has historically been dependent on oil-based materials. This innovative shoe exemplifies the commitment to ethical and sustainable manufacturing without sacrificing performance. The alarming fact that 95% of running shoes are made from oil underscores the urgency of this sustainable mission.

By creating the SuperNatural Runner, the product of three years of intensive research and the analysis of millions of strides, Circle Sportswear is setting new standards in the fusion of science, technology, and environmental consciousness. This innovation is fueled by a blend of natural materials including RWS certified wool, TENCELTM Lyocell by Lenzing, and the distinctive PLNT-FOAM™, which is partially made from castor beans in partnership with Arkema. This unique blend allows for minimal environmental impact while ensuring optimal running comfort at every stride.

The collaboration with biomechanical experts, who analysed over a million strides, resulted in a lightweight, high-performance shoe that at size 43 weighs less than 300 grams. Collaboration is integral to the development of the SuperNatural Runner, encompassing contributions from a dedicated ecosystem of partners and athlete ambassadors. The product of this combined effort is a running shoe that not only performs exceptionally but also boasts aesthetic versatility. By joining Circle Sportswear’s pre-order project, customers have an opportunity to become part of the shoe’s development process and even contribute to finalising the shoe’s details.

The composition of the SuperNatural Runner is a testament to Circle Sportswear’s commitment to environmental responsibility and the principles of a circular economy. Every component of the shoe is carefully selected to facilitate the end-of-life phase without generating post-consumer waste. The upper part of the shoe is a blend of 100% natural, renewable, biodegradable, and recyclable materials – RWS certified wool and TENCELTM Lyocell by Lenzing. The midsole, partially made from castor beans, ensures optimal flexibility, lightness, and shape retention. The outsole, made of natural vulcanised rubber, is designed for optimal first strides. Weighing less than 300 grams at size 43 with a heel-toe drop of just 6mm, the SuperNatural Runner embodies Circle Sportswear’s mission to make sport more environmentally responsible, enabling users to care for themselves and the planet simultaneously.

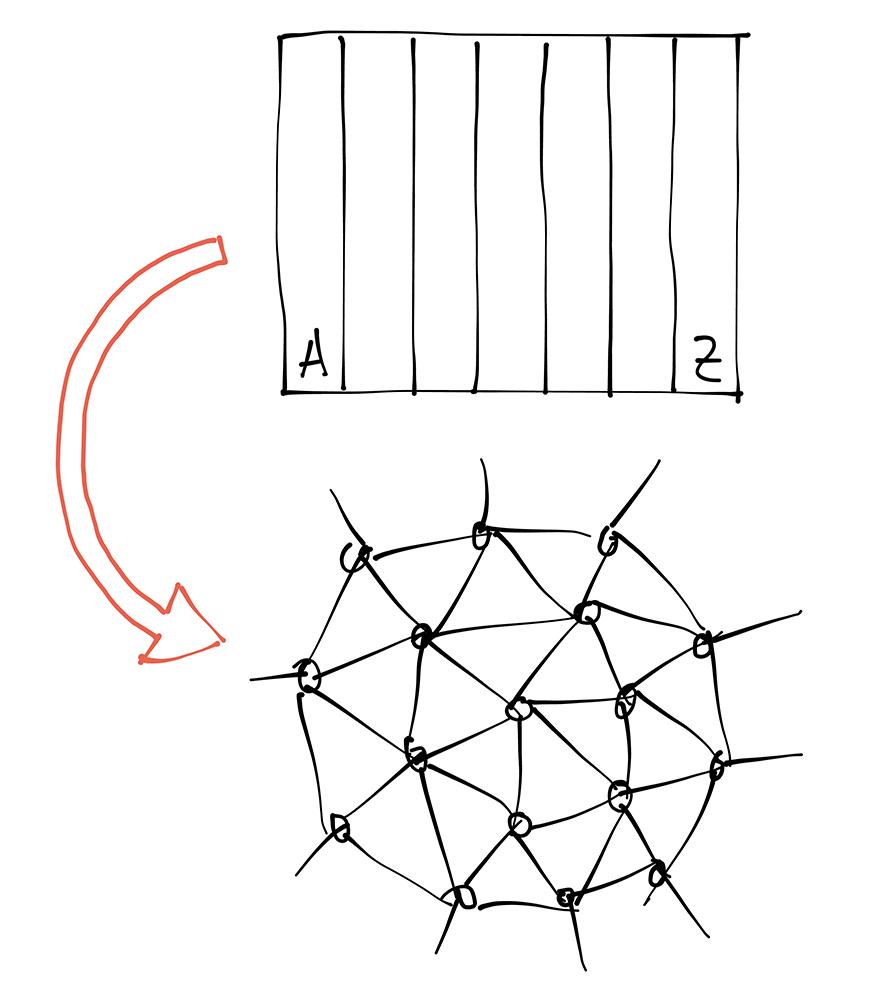

You don’t know how to start a supply chain?

By joining our network you gain access to a wealth of experience in the industry so we can guide your first steps into starting your own enterprise. Our textile engineers will help bring your ideas to life by supporting your supply chain creation and collaborating with your project when you need a helping hand. From sourcing raw materials to entering the industry’s network, we’re here to shed light on all you need to know and provide a dash of inspiration.

Collaboration

Progress in Every Step

Collaboration is integral to the development of the SuperNatural Runner, with input from their dedicated ecosystem of partners and athlete ambassadors. This joint effort has resulted in a shoe that will not only perform exceptionally but is also aesthetically versatile.

A critical part of the design is the PROWEAVE technology-developed upper, a composition of 65% RWS certified wool, and 35% wood fibre, TENCELTM Lyocell by Lenzing. This synergy results in a thermo-regulating, breathable, and durable shoe upper that hugs the foot comfortably. Circle Sportswear is also opening the doors of collaboration to their customers.

By joining their pre-order project, you get to discover the behind-the-scenes development, testing, and manufacturing processes. Plus, you’ll play a pivotal role in choosing the final details of the SuperNatural Runner – Edit 001.

“We have worked with biomechanical experts who have analysed more than 1 million strides to ensure the performance, lightness and comfort of this pair, which at size 43 weigh less than 300 grams.”

– Romain Trebuil, Circle Sportswear CEO

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Certified by Control Union

CU 857224

Run responsibly

The Responsible Wool Standard (RWS), as implemented in Circle Sportswear’s groundbreaking SuperNatural Runner through the usage of our Roller RWS yarn consisting of 100% RWS certified wool, offers unparalleled benefits to the entire value chain, from the sheep to the shoe.

- Upholding animal welfare: RWS respects the ‘Five Freedoms’ of animals, endorsing high-standard care, and promoting good health practices.

- Sustainable land management: RWS farmers preserve soil, control erosion, maintain biodiversity, and practice responsible land management.

The SuperNatural Runner’s RWS certified wool:

- Assures traceability: Each wool sourcing step, from pasture to shoe, is tracked, enhancing consumer confidence.

- Minimizes oil-dependency: The RWS promotes renewable resources, stepping towards sustainability.

In essence, Circle Sportswear’s RWS certified SuperNatural Runner, balances performance, animal welfare, land management, and traceability—pushing the running industry towards sustainability.

Collaboration Partners

Circle Sportswear

Circle is a french eco native brand which combines sustainability and performance to create high quality sportswear and shoes made for Running, Training and Yoga. Their mission is to build a new circular model and create a truly positive impact on the sport & fashion industry. Environmental and social impact is at the heart of their mission. Innovation, at its origin. They aim to inspire athletes to a new game, more conscious, more fun and empower all runners to protect our playground.

The Woolmark Company

The Woolmark Company is a global authority on wool, highlighting Australian wool’s position as the ultimate natural fibre and premier ingredient in luxury apparel. The Woolmark logo is one of the world’s most recognized and respected brands, providing assurance of the highest quality and representing pioneering excellence and innovation from farm through to finished product.

Südwolle Group

Südwolle Group is a global producer of worsted yarn in pure wool and wool blends for weaving, circular, flat knitting and technical applications with collections focused on different segments of the global textile market. The company, with over 3000 employees globally, has production facilities in Germany, Italy, Poland, Romania, Bulgaria, China and Vietnam and is located in the Nuremberg metropolitan area of Germany.

Interested in a collaboration?

If you’re not sure where to start, we can connect you with one of our supply chain managers to find the right innovation for your business.

Product description

Circle Sportswear SuperNatural Runner

The SuperNatural Runner is a testament to the commitment to a circular economy and environmental responsibility. Each component of the shoe has been carefully selected to facilitate a very low impact at its beginning of life and its end-of-life phases, without generating post-consumer persistent waste.

The shoe’s upper is composed of a blend of our Roller RWS yarn and TENCELTM Lyocell by Lenzing—both 100% natural, renewable, biodegradable, and recyclable materials, with a lining of Merino wool for great thermal regulation and moisture wicking. Furthermore, the SuperNatural Runner offers excellent cushioning while having a low environmental impact due to its ability to be recycled without loss of performance properties. The shoe’s midsole is partially created from castor beans, offering optimal flexibility, lightness, resilience, and shape retention. Lastly, the dynamic outsole, designed to facilitate the first stride, is made of a Biodegradable TPU with a high bio-based content.

Each shoe weighs less than 300 grams and sports a heel-toe drop of just 6mm. The SuperNatural Runner is a perfect embodiment of our mission: to make sport more environmentally responsible, allowing everyone to take care of themselves and the planet simultaneously.

Contents:

- Roller RWS, Nm 28/1 100% Wool 27.5 RWS

Special features:

- Sustainable manufacturing

- High-performance capability

- Innovation through natural materials

- Reduced environmental impact

- Optimised running comfort

- Traceable raw material through RWS certification